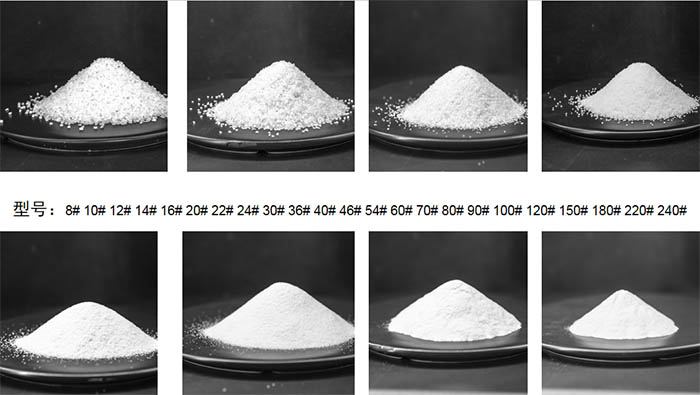

White corundum 220 mesh and 240 mesh for sand blasting for turbine parts cleaning

The color is white, the hardness is slightly higher than brown corundum, high purity, good self-sharpening, strong grinding ability, low calorific value, high efficiency, acid and alkali corrosion resistance, high temperature resistance, and good thermal stability. It is suitable for precision casting, refractory materials, grinding, sandblasting, polishing materials, spraying materials, chemical catalyst carriers, special ceramics, etc.

Production process of white corundum

White corundum is made of high-quality aluminum oxide powder as the main raw material, which is smelted at high temperature in an electric arc furnace.

White corundum micropowder is made of high-quality aluminum oxide powder as the main raw material, which is melted at high temperature in an electric arc furnace to form white corundum blocks, which are crushed into small pieces by a jaw crusher, and secondary crushed by a ball mill to make the particles smaller, and then pickled. Impurities are removed, siphon is segmented, stirred and precipitated to extract different models on time, and then dried and sieved through sedimentation to loosen.

Physical properties of white corundum

| Moh’s hardness | 9.0 |

| Bulk density | 1.75-1.95g/cm³ |

| true density | 3.95g/cm³ |

| Bulk density | 3.6 |

| melting point | 2250℃ |

| Maximum operating temperature | 1900℃ |

Chemical composition and chemical content of white corundum

| Al2O3 | Fe2O3 | Na2O | SiO2 | |

| Segment sand | 99.5% | 0.04% | 0.06% | 0.3% |

| Fine powder | 99.0% | 0.1% | 0.08% | 0.35% |

| Granular sand | 99.5% | 0.04% | 0.04% | 0.23% |

| Micronized | 99.2% | 0.06% | 0.08% | 0.35% |

The use of white corundum: iron workpiece rust removal, decontamination, descaling and increasing plating and coating adhesion; Aluminum workpiece descaling, surface strengthening, light decoration;Copper workpiece de-oxide matte effect, glass products crystal frosted, engraved pattern Plastic products matte effect, denim and other special fabrics plush processing and effect patterns。

1Surface processing: metal oxide layer, carbide black skin, metal or non-metal surface rust removal, such as gravity die casting mold, rubber mold oxide or release agent removal, ceramic surface black spots, uranium color removal, painted rebirth.

2, beautification processing: all kinds of gold,KMatting or matte treatment of gold jewelry, precious metal products, crystal, glass, corrugation, acrylic and other non-metallic matte processing, and can make the surface of the processed object into a metallic luster.

3Etching processing: jade, crystal, agate, semi-precious stones, seals, elegant stones, antiques, marble tombstones, ceramics, wood, bamboo pieces, etching art.

4, pretreatment processing: Teflon (TEFLON),PU, rubber, plastic covering, rubber roller barrel (ROLLER), electroplating, metal spray welding, titanium plating, etc. before treatment, so that the surface adhesion increases.

5Burr processing: bakelite, plastic, zinc, aluminum die-casting, electronic parts, magnetic core, etc.

6Stress relief processing: aerospace, national defense, precision industry parts, rust removal, paint removal, matting, refurbishment, etc。