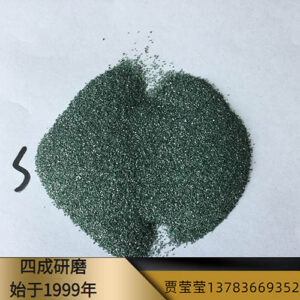

Green silicon carbide is made of petroleum coke and high-quality quartz sand as the main raw materials, adding salt as additives, and smelting at high temperature in a resistance furnace. It is green crystalline, brittle and sharp, and has certain thermal and electrical conductivity. Green silicon carbide powder is made of high-quality large crystalline green silicon carbide block after crushing, vertical ball mill particle shaping, pickling moisture, hydraulic precision classification, natural settlement after high temperature drying.

| Knoop hardness | 2600 |

| Mohs hardness | 9.4above |

| melting point | 2600 |

| specific gravity | 3.2g/cm³ |

| Granular | Angular and irregular |

| color | green |

| SIC | 99.05 |

| SiO2 | 0.2 |

| F.Si | 0.03 |

| F.Fe | 0.04 |

| C | 0.1 |

Uses of green silicon carbide

Green silicon carbide granular sand:

4# 5# 6# 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220 #

It is mainly used as a sandblasting medium for mold making and surface treatment

Mold manufacturing: resin grinding wheel, ultra-thin cutting disc, marble grinding wheel, diamond grinding disc

Surface treatment: grinding cemented carbide, hard brittle metal and non-metallic materials—Quartz glass, optical glass, piezoelectric ceramics, etc

Green silicon carbide powder:

JIS240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# 10000 #

Green silicon carbide powder can be used for precision grinding of hard glass, slicing of monocrystalline silicon and polycrystalline silicon rod, precision grinding of monocrystalline silicon wafer, processing of superhard metals, processing of soft metals such as copper and copper alloys, processing of various resin materials, etc.