Brown corundum|Henan Sicheng Grinding Technology Co., Ltd

Brown corundum is made of high-quality bauxite, iron filings, anthracite smelting in the arc at high temperature, crushed and shaped by self-mill, magnetic separation and iron removal, sieving into a variety of particle sizes, the main chemical component is Al2O3, its content is 92%–97%, and contains a small amount of Fe, Si, Ti, etc. Its texture is dense, high hardness, tan, toughness, grain formation of spherical shape, suitable for the manufacture of ceramics, resin high consolidation abrasives and grinding, polishing, sandblasting, precision casting, refractory materials, etc.

Chemical composition content:

| Al2O3 | 94.8% |

| SiO2 | 1.4% |

| TiO2 | 3.2% |

| Fe2O3 | 1.2% |

Physical characteristics:

| project | index | project | index |

| color | brown | Hardness (Mohs) | ≥9.0 |

| Crystal form | Trigonal crystal system | Melting Point(°C) | 2250 |

| specific gravity | 3.95g/cm3 | Operating temperature(°C) | 1850 |

| Bulk density (g/cm3) | 1.53-1.99 | True density (g/cm3) | 3.6-3.95 |

Production process

use

–for refractory materials

Segment sand:0-1 1-2 3-5 5-8 8-12mm…

Fine powder:100#-0 200#-0 320#-0/325#, etc

Used in steel, casting, petrochemical, breathable bricks, ladle lining, castables, prefabricated parts, ceramics and other fields, is an excellent refractory raw material. High refractory, high hardness, good thermal shock stability, good erosion resistance and wear resistance, stable performance.

Main uses: refractory materials, charge, castables, ramming materials, plastics, spray feeding, pressing, projectiles, coatings, spray coatings, fire mud, dry vibrating materials, artesian castables, coatings, refractory muds, etc. Such as: unshaped refractories, stereotyped refractories, corundum bricks, ladle refractories, neutral refractories, blast furnace hot blast furnace series combination bricks, high aluminum bricks, carbon-containing refractories, mullite bricks, cannon mud, spray guns, bulk materials, ceramic cups, clay bricks, combination bricks, corundum products, etc.

–Abrasives

Main models: 36# 46# 54# 60# 80# 100# 120# 150# 180# 220# 240# 280# 320 #wait

Abrasive belts, emery cloths, sandpaper, etc. coated with abrasives and resin grinding wheels and other consolidated abrasives, grinding sharp, heating rate is very low, grinding ratio is high, and less adhesion when used; The sintered abrasive made has the characteristics of no network cracks and no rust spots after firing.

F sand is used for resin, ceramic grinding wheel; P sand is used for the production of coated abrasives, such as emery cloth sandpaper.

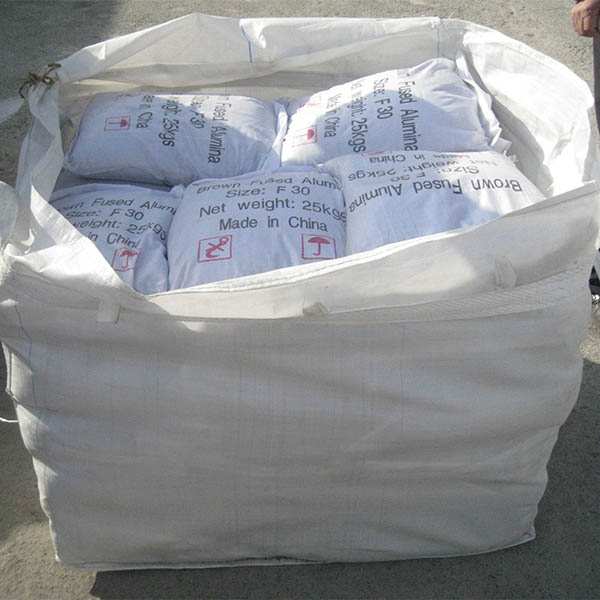

wrap:

25 kg lined woven bag, can be added to tons of bags or pallets