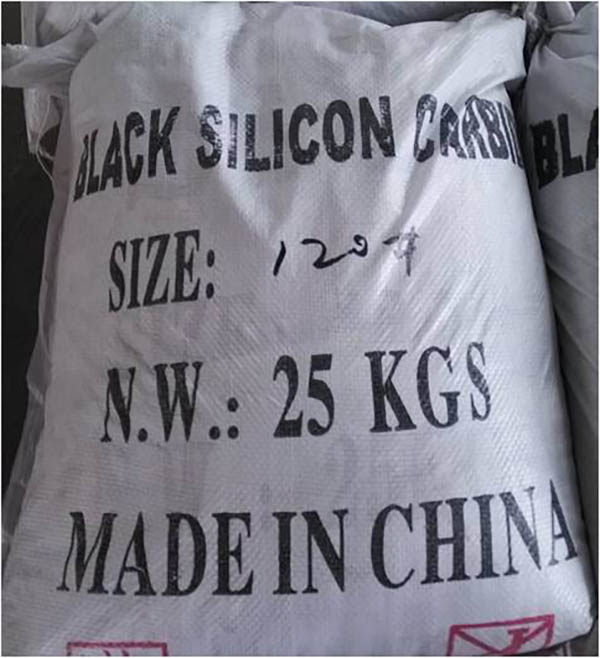

Black silicon carbide manufacturers produce first-grade black silicon carbide 80 mesh stone grinding with black emery

Black silicon carbide is made of quartz sand, petroleum coke (or coal coke), wood chips and other raw materials through high-temperature smelting in an electric resistance furnace. It becomes black and opaque, hexagonal crystal, and the Mohs hardness is 9.16-9.5. It is second only to diamond . And boron carbide, the performance is brittle and sharp and has a certain degree of conductivity.

Black silicon carbide contains about 98% SiC , and its toughness is higher than that of green silicon carbide. It is mostly used for processing materials with low tensile strength, such as glass, ceramics, stone, refractory materials, cast iron and non-ferrous metals, optical glass, ceramics and other non-metals. Material.

| Physical properties of black silicon carbide | |

| Moh’s hardness | 9.15 |

| melting point | 2250℃ |

| Maximum operating temperature | 1900℃ |

| true density | 3.2-3.4g/cm³ |

| Microhardness | 2840-3320kg/ m² |

| Black silicon carbide chemical composition | |

| SiC | ≥98% |

| F.C | ≤0.30% |

| H2O3 | ≤1% |

| SIO2 | ≤1% |

| Fe2O3 | ≤0.30% |

| Magnetic substance content | ≤0.02 |

| model Black silicon carbide grain size sand 8# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220 # Black silicon carbideMicronized In标 W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 Gb F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 Day standard 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000 # | |

| Uses of black silicon carbide: Black silicon carbide is made of quartz sand,Petroleum coke and high-quality silica are the main raw materials,It is smelted at high temperature by resistance furnace. Its hardness is between corundum and diamond,The mechanical strength is higher than corundum,Sexual brittle and sharp. Green silicon carbide is based on petroleum coke and high-quality silica as the main raw materials,Salt is added as an additive and smelted at high temperature by a resistance furnace. Its hardness is between corundum and diamond,The mechanical strength is higher than corundum. So what are the main uses of silicon carbide? 1Abrasive–Mainly because silicon carbide has high hardness, chemical stability and certain toughness, so silicon carbide can be used in the manufacture of consolidation abrasives, coated abrasives and free grinding, so as to process glass, ceramics, stone, cast iron and some non-ferrous metals, cemented carbide, titanium alloys, high-speed steel tools and grinding wheels. 2, refractory materials and corrosion-resistant materials—Mainly because silicon carbide has a high melting point(Decomposition), chemical inertness and thermal vibration resistance, so silicon carbide can be used in abrasives, ceramic products firing kiln used in the shed and box, zinc smelting industry vertical cylinder distillation furnace silicon carbide bricks, aluminum electrolytic cell lining, crucibles, small furnace materials and other silicon carbide ceramic products. 3, chemical use–Because silicon carbide can decompose in molten steel and react with oxygen separation and metal oxides in molten steel to form carbon monoxide and silicone-containing slag. Therefore, it can be used as a purifying agent for smelting steel, that is, as a deoxidizer for steelmaking and a cast iron structure improver. This generally uses low-purity silicon carbide to reduce costs. At the same time, it can also be used as a raw material for the manufacture of silicon tetrachloride. 4, electrician use–Used as heating elements, nonlinear resistance elements and high semiconductor materials. Heating elements such as silicon carbon rods(Applies to1100~1500Various electric furnaces working at °C), nonlinear resistance elements, various lightning arresting valve plates. 5, other formulated into far-infrared radiation coating or made of silicon carbide silicon board with far-infrared radiation dryer. | |