0-1-3-5-8mm brown corundum segment sand refractory aggregate brown corundum refractory material

Brown corundum is made of high-quality bauxite, iron filings, and anthracite in an electric arc at high temperature. It is crushed and shaped by an autogenous mill, iron is removed by magnetic separation, and it is sieved into various particle sizes. The main chemical component is Al2O3, and its content is 92%. –97%, and also contains a small amount of Fe, Si, Ti, etc. It has dense texture, high hardness, tan color, high toughness, and spherical particles. It is suitable for manufacturing ceramics, resin high-consolidation abrasives, grinding, polishing, sandblasting, precision casting, refractory materials, etc.

Chemical composition content:

| Al2O3 | 94.8% |

| SiO2 | 1.4% |

| TiO2 | 3.2% |

| Fe2O3 | 1.2% |

Physical properties:

| project | index | project | index |

| color | brown | Hardness (Mohs) | ≥9.0 |

| crystal form | Trigonal system | Melting point (°C) | 2250 |

| proportion | 3.95g/cm3 | Operating temperature (°C) | 1850 |

| Bulk density (g/cm3) | 1.53-1.99 | True density (g/cm3) | 3.6-3.95 |

Production Process

use

– For refractory materials

Segment sand: 0-1 1-2 3-5 5-8 8-12mm…

Fine powder: 100#-0 200#-0 320#-0/325# etc.

It is an excellent refractory material used in iron and steel, foundry, petrochemical, breathable brick, ladle lining, castable, prefabricated parts, ceramics and other fields. High refractoriness, high hardness, good thermal shock stability, good corrosion resistance and wear resistance, and stable performance.

Main uses: refractory materials, furnace charge, castable material, ramming material, plasticizable material, gunning material, pressing material, projection material, smearing material, spray coating, fire clay, dry vibrating material, self-flowing castable material, coating, refractory Mud etc. Such as: unshaped refractory materials, shaped refractory materials, corundum bricks, refractory materials for ladles, neutral refractory materials, combined bricks for blast furnace hot blast stoves, high alumina bricks, carbon-containing refractory materials, mullite bricks, gun mud, spray guns , bulk materials, ceramic cups, clay bricks, combined bricks, corundum products, etc.

-Abrasives _

Main model 36# 46# 54# 60# 80# 100# 120# 150# 180# 220# 240# 280# 320# etc.

Coated abrasives such as abrasive belts, abrasive cloths, sandpaper, etc. , and bonded abrasives such as resin grinding wheels, have sharp grinding, low heating rate, high grinding ratio, and less adhesion during use; the sintered abrasives produced have the characteristics of firing It has the characteristics of no net cracks and no rust spots.

F sand is used for resin and ceramic grinding wheels; P sand is used for the production of coated abrasive tools, such as emery cloth and sandpaper.

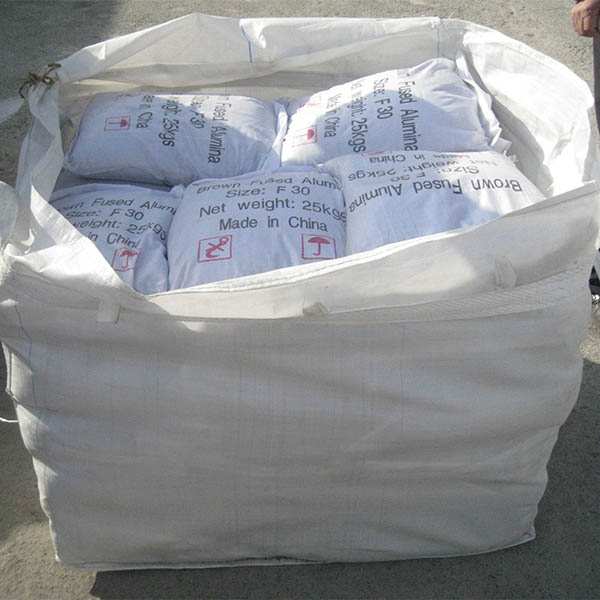

Packing :

25 kg lined woven bag, can be added ton bags or pallets