Crucible sagger production with corundum white corundum grain size sand 46 mesh 54 mesh 120 mesh 150 mesh

1. Product Introduction

White corundum is made of high-quality aluminum oxide powder and smelted by electric melting. It has white color, high hardness, low toughness, high purity, excellent self-sharpening, strong grinding force, low heat generation, high efficiency, It has the characteristics of acid and alkali corrosion resistance, high temperature resistance and good thermal stability.

| Physical indicators of white corundum | |||

| color | White | Moh’s hardness | 9.0 |

| Bulk density | 3.60g/cm3 | true density | 3.90g/cm3 |

| melting point | 2250℃ | Operating temperature | 1900℃ |

| Chemical content | |||

| Al2O3 _ _ _ | 99.5% | Na2O | 0.30% |

| Fe2O3 | 0.06% | SiO2 | 0.06% |

| Packing: 25KG/lined woven bag, pallet or ton bag can be added | |||

| Production standard: P sand, European standard FEPA, Japanese standard JIS, Chinese GB or processing according to customer requirements | |||

| Particle size: 4#-12000# 0-1 1-3 3-5 5-8mm, etc. -100 -200 -220 -325 mesh… | |||

2. Purpose

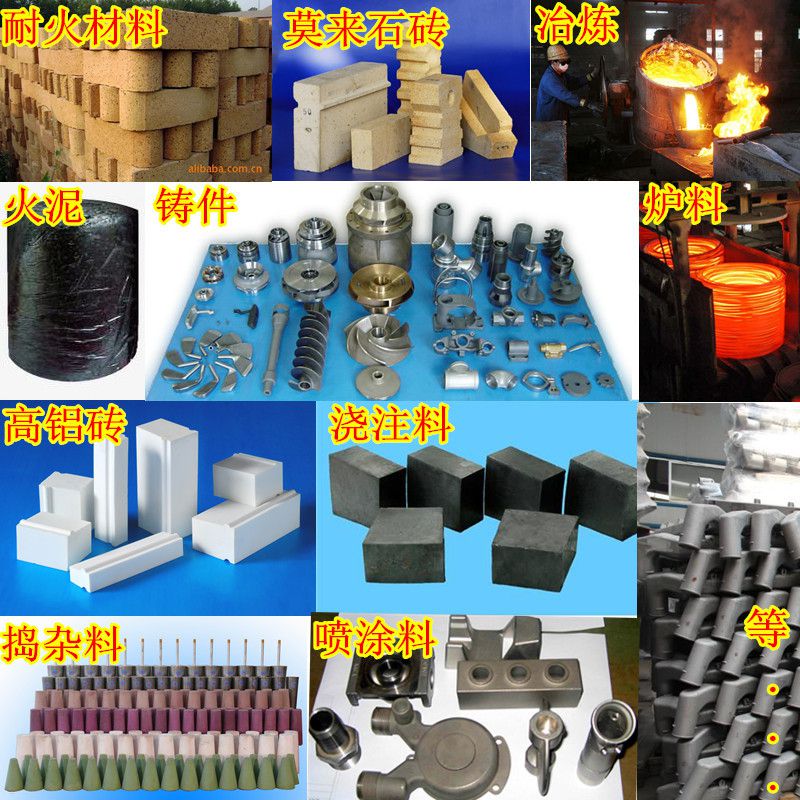

– For refractory materials

Segment sand: 0-0.2 0-0.3 0-0.5 0-1 0-2 0-3 0-5 1-2 1-3 2-3 2-5 3-5 5-8 3-8 8-12 12- 30mm…

Fine powder: 100#-0 200#-0 320#-0 325#-0, etc

Used in steel, casting, petrochemical, breathable bricks, ladle lining, castables, prefabricated parts, ceramics and other fields, is an excellent refractory raw material. High refractory, high hardness, good thermal shock stability, good erosion resistance and wear resistance, stable performance.

Main uses: refractory materials, charge, castables, ramming materials, plastics, spray feeding, pressing, projectiles, coatings, spray coatings, fire mud, dry vibrating materials, artesian castables, coatings, refractory muds, etc. Such as: unshaped refractories, stereotyped refractories, corundum bricks, ladle refractories, neutral refractories, blast furnace hot blast furnace series combination bricks, high aluminum bricks, carbon-containing refractories, mullite bricks, cannon mud, spray guns, bulk materials, ceramic cups, clay bricks, combination bricks, corundum products, etc.

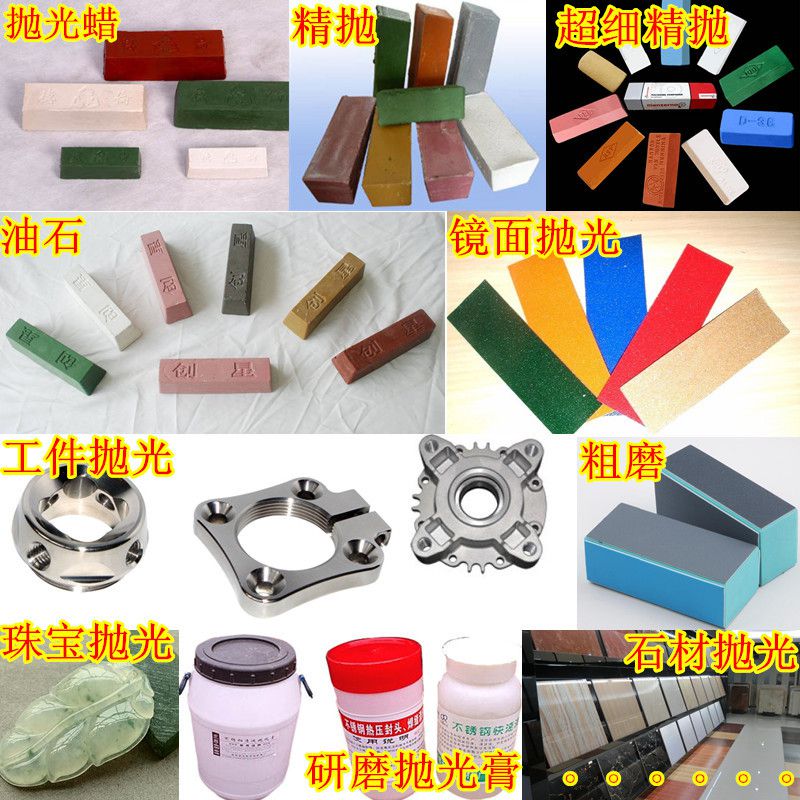

–For sandblasting, grinding and polishing

Rust removal:Main models: 8# 10#12# 14# 16# 20# 24# 30# 36# etc

Sandblasting:Main models: 36# 46# 54# 60# 80# 100# 120# 150# 180# 220# etc

Polished:Main models: 240# 280# 320# 400# 500# 600# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# 10000# etc

1 Surface finishing:Metal oxide layer, carbide black skin, metal or non-metal surface rust removal, such as gravity die casting mold, rubber mold oxide or release agent removal, ceramic surface black spots, uranium color removal, painted rebirth.

2 Beautification processing:All kinds of gold, K gold jewelry, precious metal products matting or matte treatment, crystal, glass, corrugation, acrylic and other non-metallic matte processing and can make the surface of the processed object into a metallic luster.

3. Etching processing: Etching art of jade, crystal, agate, semi-precious stones, seals, elegant stones, antiques, marble tombstones, ceramics, wood, bamboo pieces, etc.

4 Pre-treatment processing: Teflon (TEFLON), PU, rubber, plastic coating, rubber roller (ROLLER), electroplating, metal spray welding, titanium plating and other pre-treatments to increase surface adhesion.

5 Burr processing : removal of burrs from bakelite, plastic, zinc, aluminum die-casting products, electronic parts, magnetic cores, etc.

6 Stress relief processing : stress relief processing for aerospace, national defense, and precision industry parts, rust removal, paint removal, matting, and renovation.

– ideal polishing material

It can be made into abrasive polishing paste, polishing wax, oil stone, etc. or directly used for rough grinding, fine polishing, ultra-fine fine polishing, mirror polishing, etc. of various materials.

-Abrasives _

Main model 36# 46# 54# 60# 80# 100# 120# 150# 180# 220# 240# 280# 320# etc.

Coated abrasives such as abrasive belts, abrasive cloths, sandpaper, etc. , and bonded abrasives such as resin grinding wheels, have sharp grinding, low heating rate, high grinding ratio, and less adhesion during use; the sintered abrasives produced have the characteristics of firing It has the characteristics of no net cracks and no rust spots.

F sand is used for consolidated abrasives, such as resin, ceramic grinding wheel, etc.; P sand is used for the production of coated abrasives, such as emery cloth sandpaper, etc.

-ceramic products

Main model 36# 46# 54# 60# 80# 100# 120# 150# 180# 220# 240# 280# 320# 325# etc.

Special ceramics, electric ceramics, architectural and sanitary ceramics, chemical ceramics, artistic ceramics, daily-use ceramics , etc.

-Commodity processing

Main model 100# 120# 150# 180# 220# 500# 800# 1200# 1200# 1500# 3000# etc.

Such as sandblasting and polishing of buttons, tableware, denim, crystal products, jewelry and jade.

3. Product advantages:

1. Does not affect the color of the workpiece;

2. It can be used for sandblasting in the process where iron powder residue is strictly prohibited;

3. Micro-powder grade is very suitable for wet sandblasting and polishing operations;

4. Fast processing speed and high quality;

5. The amount of iron oxide contained is extremely low, suitable for sandblasting operations where iron residues are strictly prohibited;

6. Go through a pickling step to remove impurities.

4. Alias of white corundum:

White emery, fused alumina, white jade, corundum, Al2O3, alumina, alumina, polishing powder, polishing paste, etc.

Product packaging:

Six, the main customer groups:

Refractory materials, foundries, washing plants, denim sandblasting, workshops, shipyards, ship repair yards, steel mills, micro powder plants, grinding wheel plants, sandpaper emery cloth plants, crystal glass industry, building floor industry, steel industry, hardware industry, electronics industry, car manufacturing industry, coastal wharf parking lot, stadium floor bone, sandblasting industry, etc.