Sintered plate-like corundum for ladle castable has good thermal shock resistance and peeling resistance

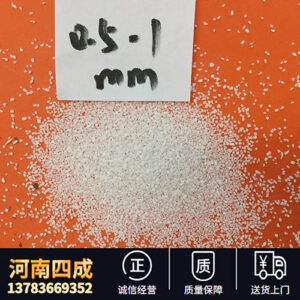

Tabular corundum is a fully recrystallized -AL2O3, which is batched, ground and shaped and sintered at a temperature slightly lower than the melting point of imported alumina. The crystals are staggered in a table line, which increases the mechanical strength of the particles. The closed pores are mainly evenly distributed inside and between the particles, with high bulk density, low apparent porosity, and low water absorption, which reduces the amount of liquid used in the reprocessed product

| Model | chemical composition | Physical indicators | |||||

| Al2O3 | SiO2 | Fe2O3 | Na2O | Bulk density | Water absorption | Apparent porosity | |

| 0-1mm 1-3mm 3-5mm 5-8mm | ≥99.2 | ≤0.1 | ≤0.02 | ≤0.4 | 3.5 | 1.5 | ≤5 |

| 200#–0 320#–0 325 # | ≥99.1 | ≤0.15 | ≤0.04 | ≤0.4 | 3.45 | 2.0 | ≤6 |

| Tabular corundum uses | Plate corundum is an ideal refractory material, which can be used as aggregate in various aluminum refractories, and can also be added to other aluminum amorphous refractories, which can be widely used in steel, casting, ceramics and other industries, among which the application in the steel industry covers almost the whole process of ironmaking and steelmaking. Applications in the steel industry 1.Sliding spout 2.Ladle castable 3.Prefabs | ||||||