What is the difference between brown corundum and white corundum? What is the difference between brown corundum and white corundum?

1. Different raw materials:

The raw material for brown corundum is bauxite, as well as anthracite and iron. The raw material of white corundum is alumina powder.

2. Different uses:

Brown corundum can be used to manufacture ceramics, resin high consolidation abrasives, grinding, polishing, sandblasting, precision casting, etc., and can also be used to manufacture advanced refractory materials. White corundum is suitable for grinding fine-grained abrasives such as high carbon steel, high speed steel and stainless steel, and white corundum can also be used for precision casting and advanced refractories.

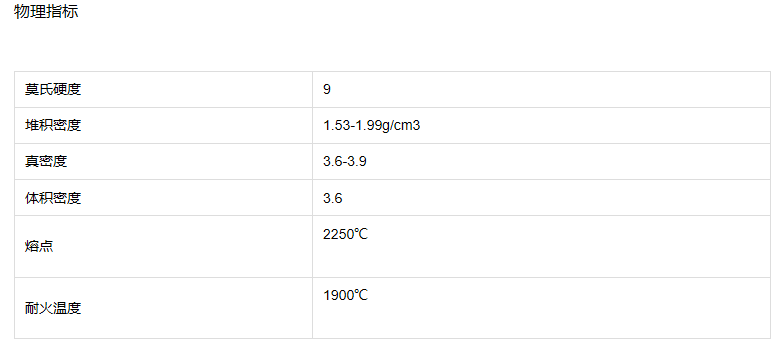

3. Different performance:

Brown corundum has the characteristics of high purity, good crystallization, strong fluidity, low coefficient of linear expansion and corrosion resistance. White corundum has the characteristics of high purity, good self-sharpening, acid and alkali corrosion resistance, high temperature resistance, and stable thermal performance. In comparison, white corundum is harder than brown corundum.

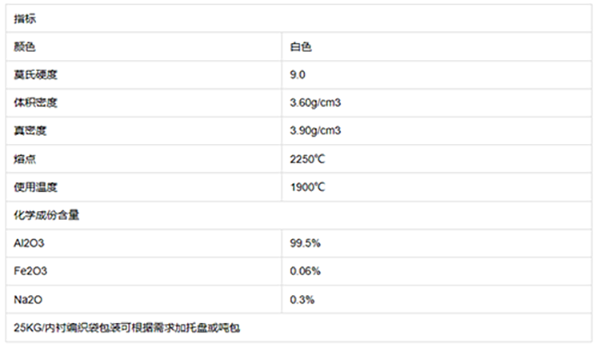

4. Different ingredients:

Although brown corundum and white corundum both contain alumina, the alumina content of white corundum is more than 99%, and the content of brown corundum alumina is about 95%.

5. Different colors:

Since the alumina content of white corundum is higher than that of brown corundum, the color of white corundum is white, and brown corundum is brown-black.

6. Production is different:

White corundum is produced with alumina powder, while brown corundum is produced from calcined bauxite.

7. Different objects of use:

White corundum is used by some high-end users, because its cutting strength is relatively good, polishing effect is also very good, mostly used for carbon steel, alloy steel, malleable cast iron, hard bronze, etc., while brown corundum is widely used in the market, but also in the market is relatively large, mostly used in flamed steel, high speed steel, high carbon steel and so on.